As the design unit for a major domestic civil aircraft model, this institute has accumulated a methodology for developing complex aircraft and systems based on ARP4754A and other systems engineering theories through long-term practice. They would like to model this methodology. Traditional tools like Word and Excel could record the processes but could not structure, visualize, or instantiate them effectively.

The product philosophy of AirEdge’s Gateflow module perfectly met the institute's needs, helping to solidify their aircraft and system development methodology through modeling, allowing for continuous reuse in subsequent model development processes.

Customer Profile

This aircraft design institute is responsible for aircraft design and development, test verification, airworthiness certification, and tackling key technologies, handling a large portion of China’s civil aircraft design and development tasks.

Challenges and Solutions

Challenge 1: Non-explicit Accumulation of Aircraft and System Development

Processes Over the long-term development of civil aircraft, the design institute has accumulated valuable engineering experience in aircraft and system development based on ARP4754A and other systems engineering theories. However, this knowledge was stored in unstructured documents, making it difficult to use directly for guiding the design and development of new models.

Solution 1

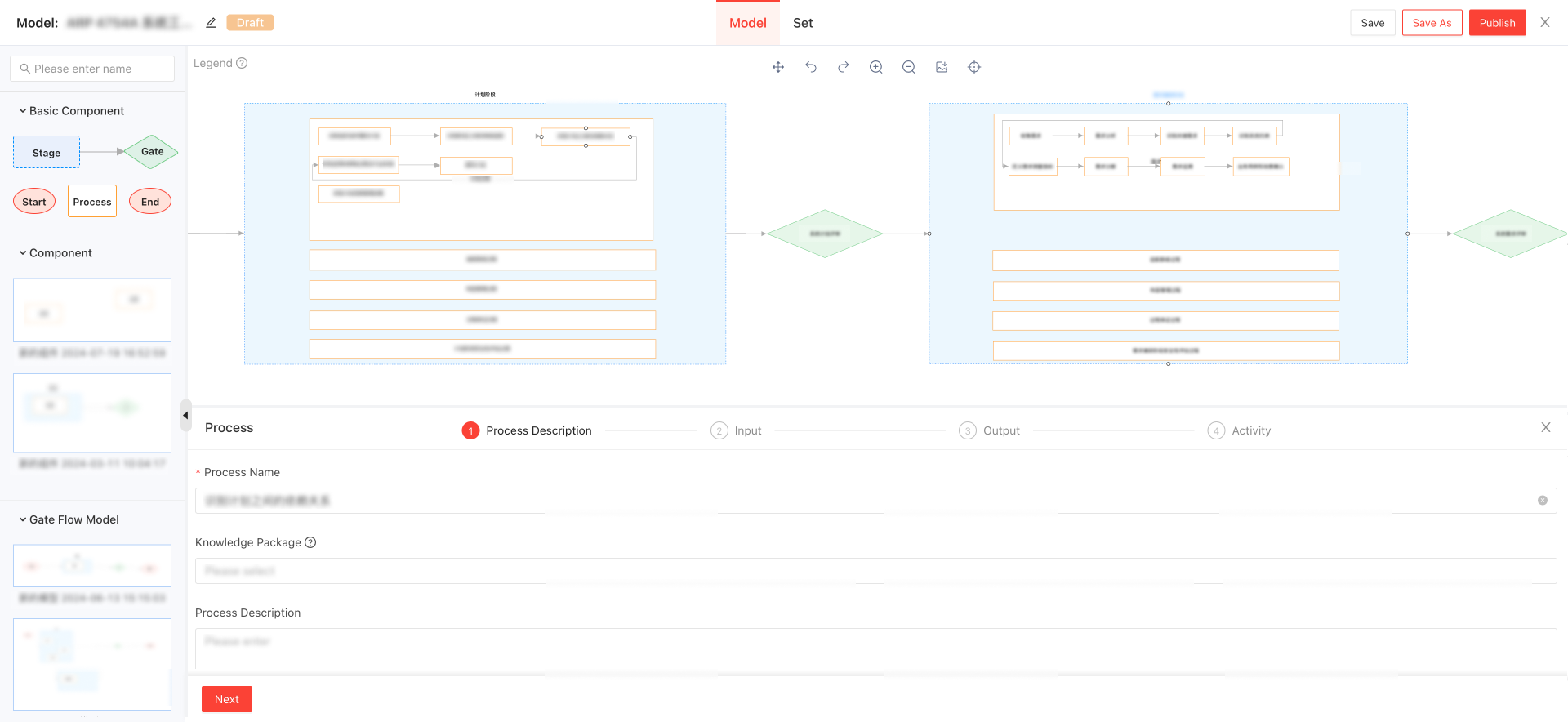

Using the process modeling solutions provided by AirEdge, the design institute established models based on the eight major ARP4754A processes. These models structured the ARP4754A development process and solidified it explicitly through modeling. The models include the eight major processes and hundreds of sub-processes, each with inputs, activities, outputs, required job capabilities, and inter-process dependencies, making them standardized, structured, and reusable. Additionally, the graphical presentation of the models made it easier for junior and mid-level engineers to understand the significance of the eight processes, helping them implement these processes in model development.

Challenge 2: Inconvenient Use of ARP4754-Related Process Assets

During the development of a certain civil aircraft model, the institute not only established the eight major process models but also created templates, examples, checklists, and guides for how to implement, execute, document, and verify these processes. These valuable assets could significantly aid future models and projects. However, stored as documents, they were difficult to access, and many employees were unaware of their existence, leaving these valuable assets underutilized.

Solution 2

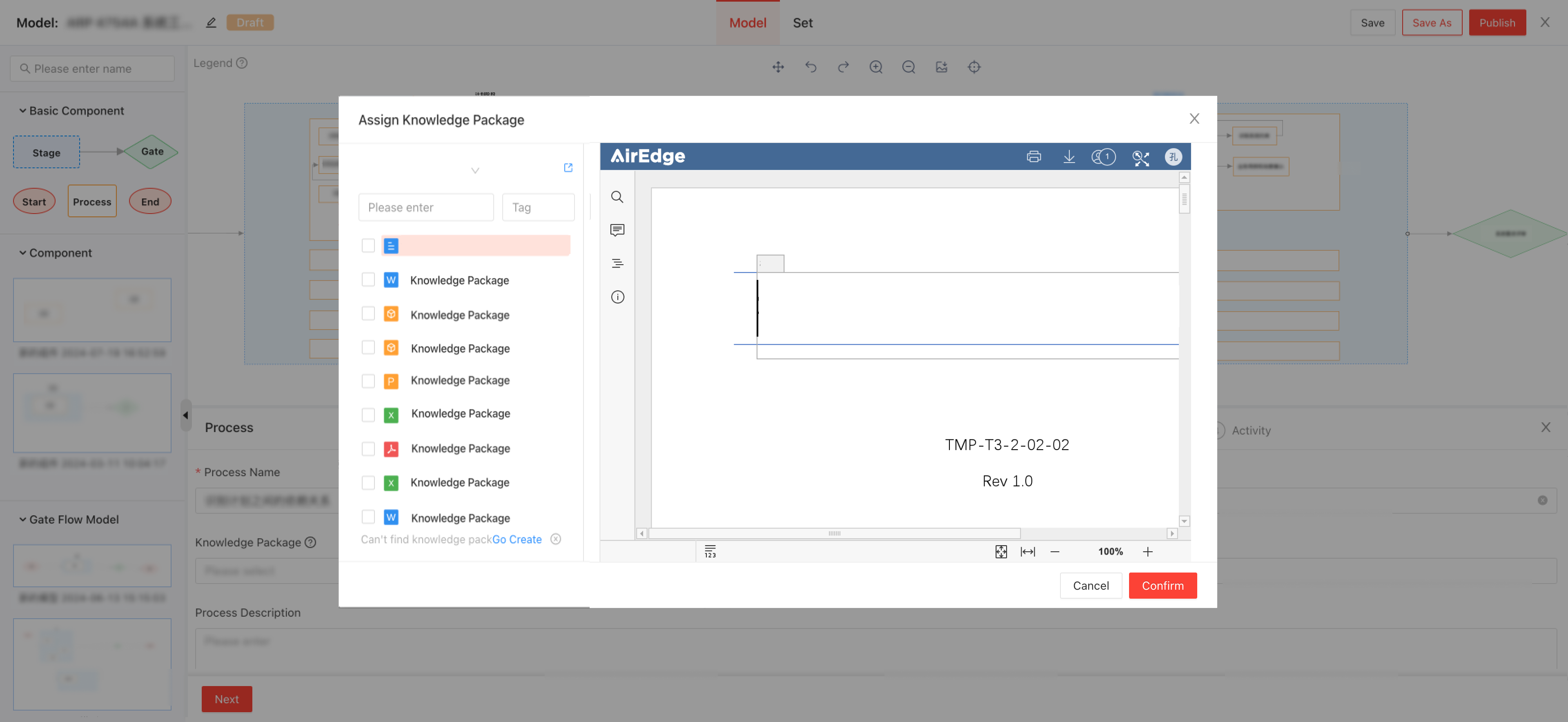

Using the Gateflow process modeling tool, the design institute attached mandatory and optional knowledge packages to the inputs, outputs, and activities of the processes or sub-processes. These knowledge packages included templates, examples, checklists, and guides. The institute has linked over 100 corresponding knowledge package files to the models.

Consequently, engineers can easily find the relevant guidance documents and templates during the development process, greatly improving the efficiency and maturity of their outputs. Moreover, structured checklists ensure uniform standards for output recognition and enhance collaboration between leaders and workers during output recognition.

Challenge 3: Unclear Usage of the Eight Major Processes by Various Departments

Despite having a unified system process model for systems engineering development, each specific system had unique requirements. For example, the landing gear system, due to its complexity and safety level, had a different development model from the general model. After the general department established the general model, it became difficult to control the specific differences when each system used it, and the general department couldn’t grasp the usage status of the general model.

Solution 3

After the general department released the ARP4754A eight-process model in Gateflow, other system departments within the design institute referenced this general model to create application instances for their systems. If a system needed to revise the model, they had to apply to the general department, and only after approval could they make modifications. This allowed the general department to understand the usage and revision status of the models, ensuring the correct implementation and landing of the eight major process models throughout the institute.

Specializes in analyzing customer issues and proposing implementable solutions

Served:

Volant Aerotech

HemsTec

Leveraging extensive experience in aerospace engineering and project management, deeply understands customer R&D scenarios, helping clients pinpoint issues accurately, analyze problems, propose corresponding solutions, and address pain points.

More Recommendations

-

Air Transportation and Regional

A Civil Aircraft Design Institute: An Edge Tool to Managing for Managing the ARP4754A ProcessesThe product philosophy of AirEdge’s Gateflow module perfectly met the institute's needs, helping to solidify their aircraft and system development methodology through modeling, allowing for continuous reuse in subsequent model development processes.

-

Drone and eVTOL

HemsTec—Innovative UAV and Avionics Product Company Achieves 50% Improvement in Requirements Engineering EfficiencyWith the enactment of the Interim Regulations on the Management of Unmanned Aircraft Flight and the CCAR-92 Civil Unmanned Aircraft Operation Safety Management Rules, compliance in developing and certifying medium to large unmanned aircraft is essential.

-

Drone and eVTOL

Volant Aerotech: Teams Up with AirEdge to Boost Low-altitude Economy TakeoffAs a representative of the low-altitude economy, electric vertical take-off and landing aircraft (eVTOL) have attracted much attention in recent years. Volant Aerotech's VE25 eVTOL, which can carry one pilot and five passengers, has a cruising speed of 235 km/h and a range of 200-400 km, making its technical parameters and performance leading in China. AirEdge, as a one-stop R&D management platform (PLM), empowers VE25 in data management, project management, requirements management, and process navigation, breaking data silos and enhancing end-to-end data and project collaboration capabilities.

-

Hardware and Light Manufacturing

Shanghai Eastern Iron: Bringing Aviation Rigor Process Management and Supplier Collaboration to the Hardware IndustryTraditional manufacturing industries are increasingly integrating new technologies and management techniques to achieve more refined and intensive product lifecycle management, further reducing costs and improving efficiency. They are expanding their horizons beyond the domestic market to the broader international market.